DSM Instructional – Service Records

This

document covers some basic usage of service records in DSM. It is a basic walkthrough using one service

type, category and truck.

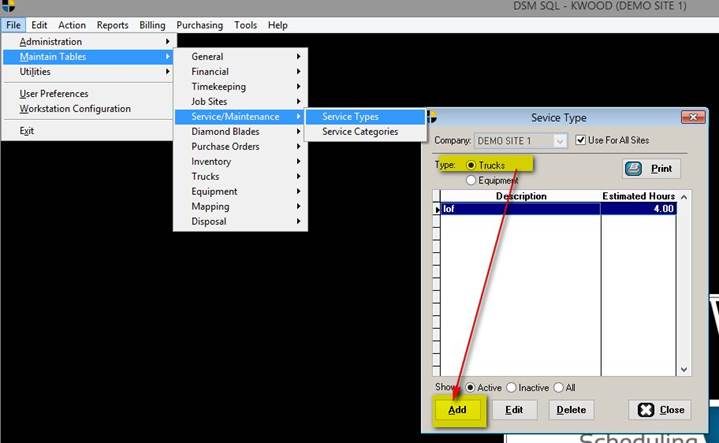

First,

let’s go set up service types. Go to

file > Maintain Tables > Service/Maintenance > Service Types. You will see the following screen:

Put

the dot next to “Trucks” and click Add.

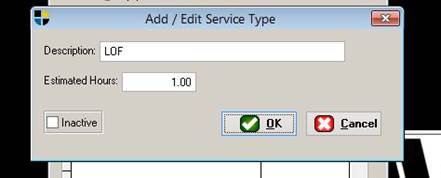

You will see the following screen:

For

now, let’s put in LOF (lube, oil, filter) and the

estimated hours it will take to perform. This is general information only.

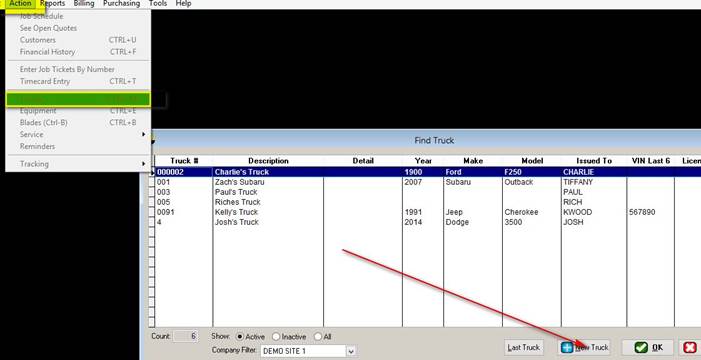

Next,

go to action > Trucks. You will see

the following screen.

Click

NEW TRUCK.

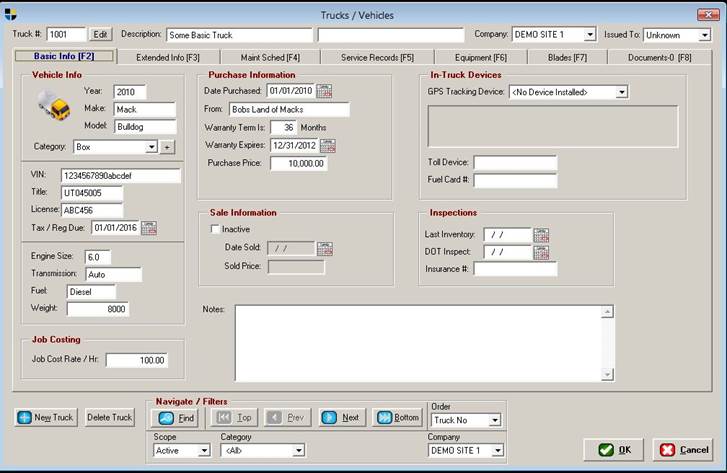

Enter

in the new truck:

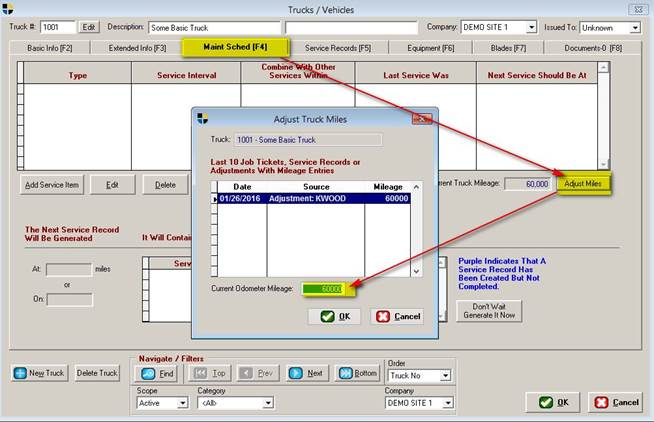

With

the basic information entered, let’s go to the MAINT SCHED tab. (F4)

With

the new truck, you must put in the mileage first. Do so by clicking ADJUST MILES:

Once complete, click OK.

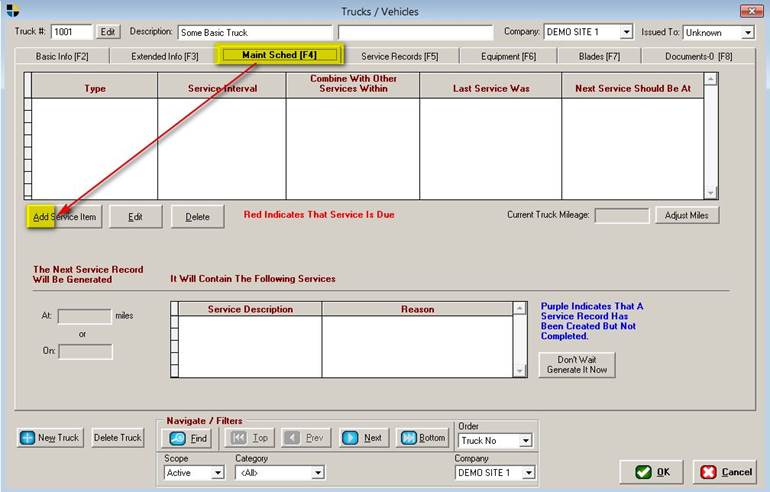

Now, let’s add a service item.

This

screen will appear. Notice that our

previously entered service type appears:

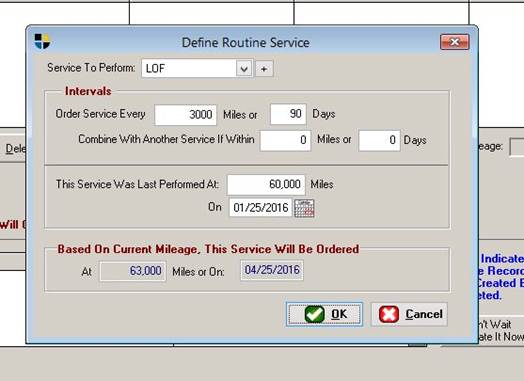

For

this example, we’re saying that at every 3000 miles, or 90 days, this truck

should have the LOF. We’ve put in the

service last performed at the exact truck mileage currently so we can go

through the process of HOW service records get created and performed.

For

now, enter the items shown above and click OK.

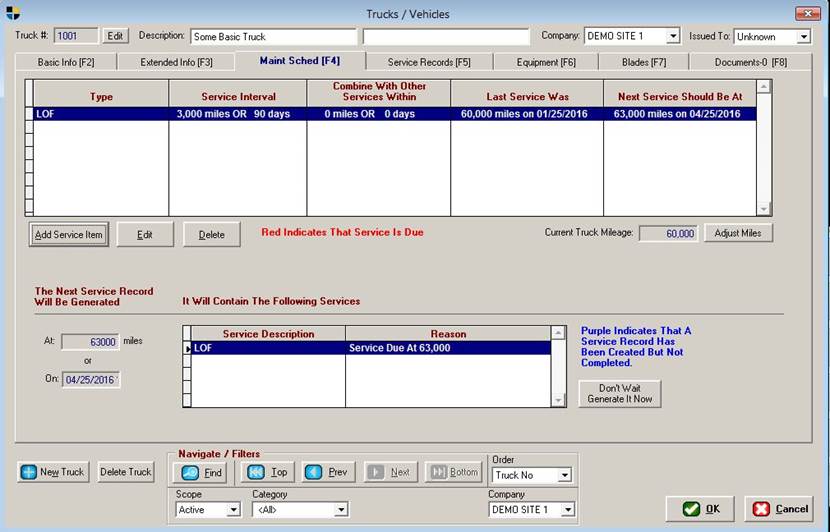

With

the Maintenance Schedule now in place, we’ll see that nothing needs to happen

at the current time.

To

get this record to show up in red or become something that action needs to be

taken, something will have to happen.

You can either generate the service now and

perform it, or you can wait for the criteria to be met. (e.g. the date, or 63000

miles)

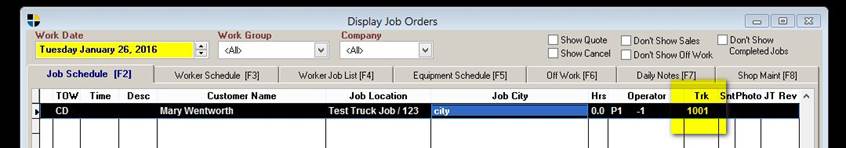

In

this case, we’ll just enter a job and use truck 1001.

Remember,

the truck record is where you assign a worker to the truck. So if you want to have the truck number

appear here, make sure your truck is assigned to the worker you assigned to the

job.

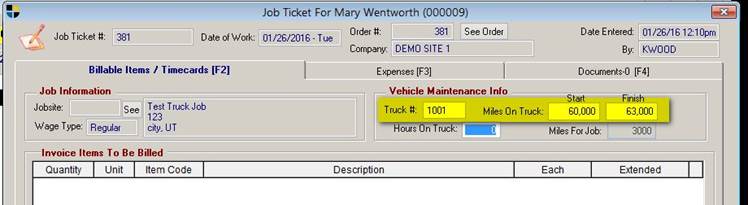

In

the system, the job ticket was updated with the current mileage that this job

took.

Ok,

so regardless of whether the job was billed or not, this truck now has a

mileage entry that should trip the service record process.

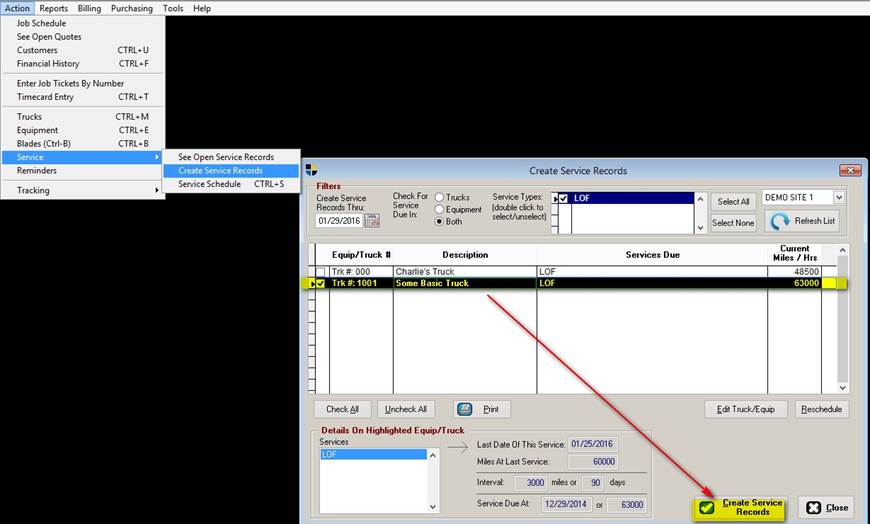

Now,

go to ACTION > SERVICE > CREATE SERVICE RECORDS.

Check

the ones you wish to create records for, and click CREATE SERVICE RECORDS at

the lower right.

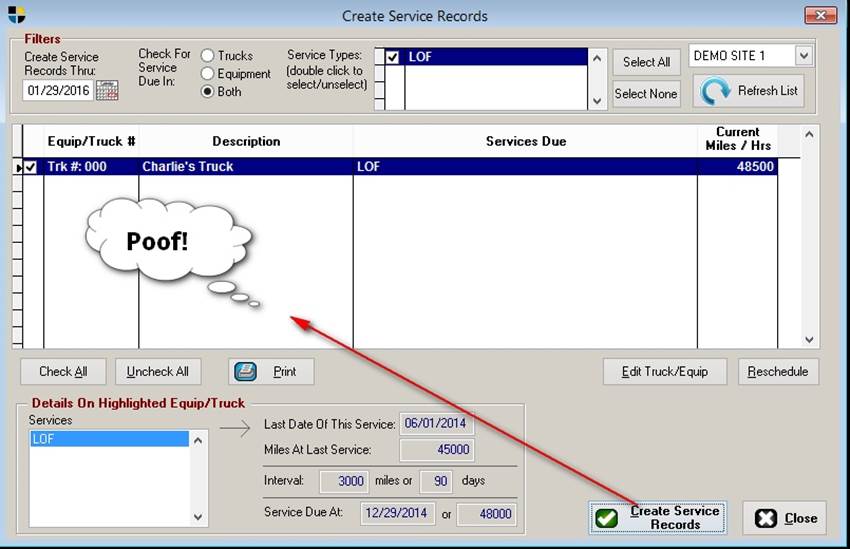

Once

you’ve clicked the button, the chosen record WAS created and will simply

disappear from the list. The initial

service record has been created.

Ignore

the fact that the newly created service record can be viewed from 4 different

places within DSM.

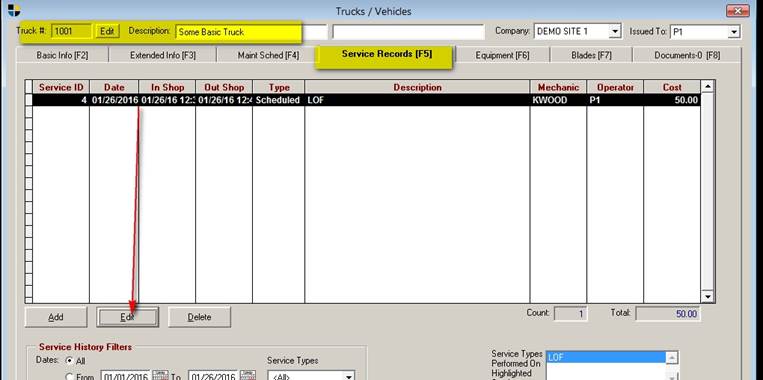

For

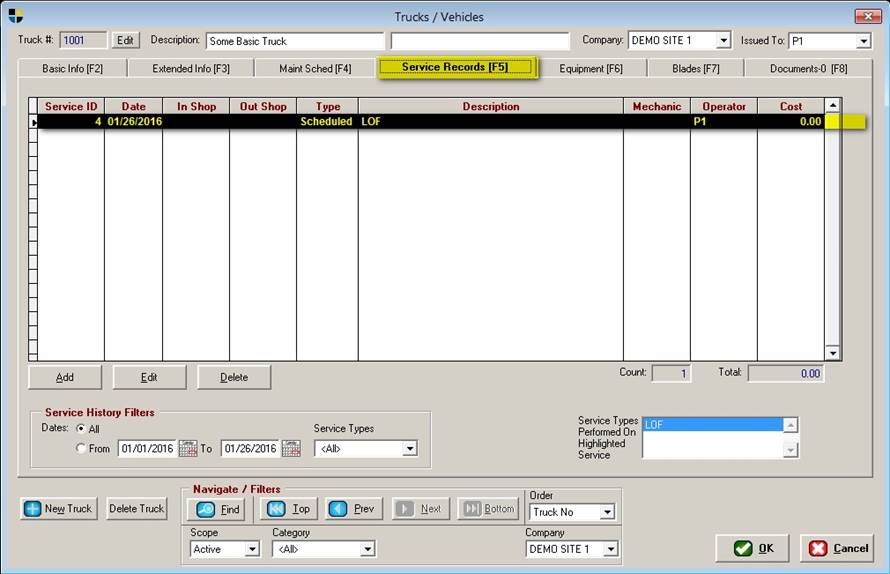

now, go back to the truck and click the Service Records tab:

You’ll

see the record waiting for action.

From

here, you can edit the record and perform the service right from the next

screen.

Click

EDIT.

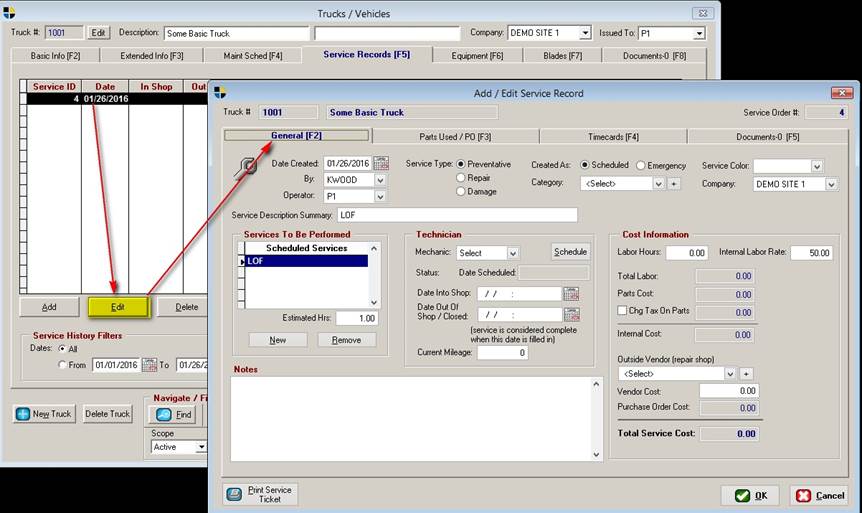

You’ll

be presented with the record itself. If

you wish, you can simply fill in the basic information for this service as it

was just a LOF.

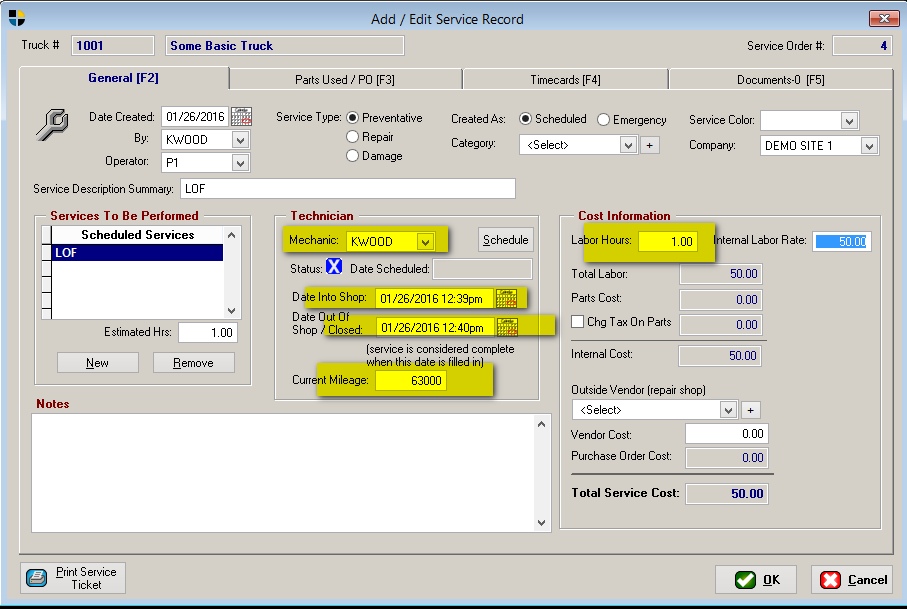

So,

for the basics: enter the mechanic, date

in, date out, current mileage and actual labor hours.

NOTE:

If you’re not tracking parts such as filters, oil, grease, etc… just click OK.

If you are then you can go MUCH further here & click the parts used

TAB, the TIMECARDS tab and even the documents tab to store other information

such as warranty items, etc.

For

now, we’ll just click OK and move on to a report.

Click

ok. You will return to the truck’s

service records tab and you can close from there.

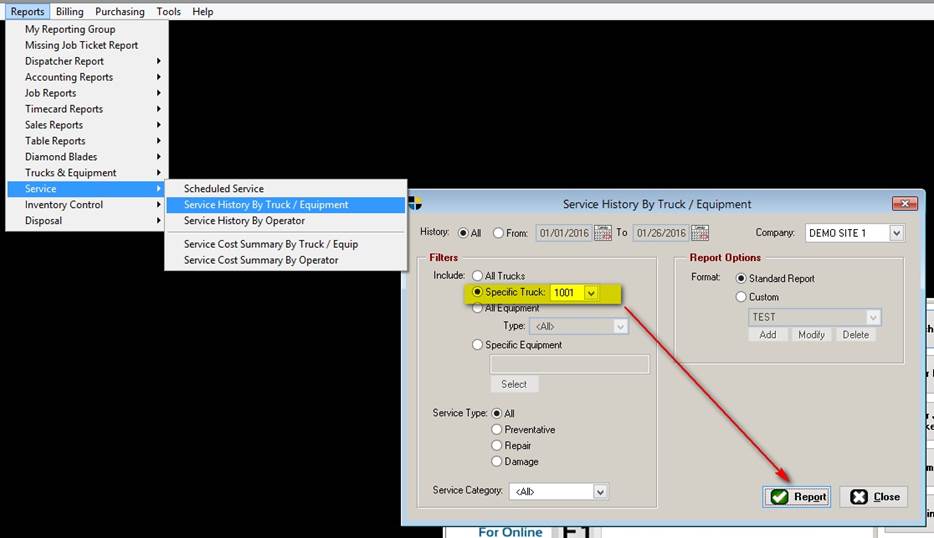

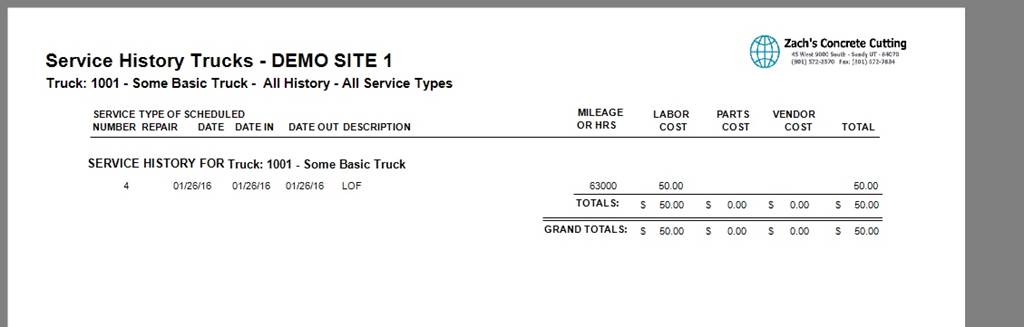

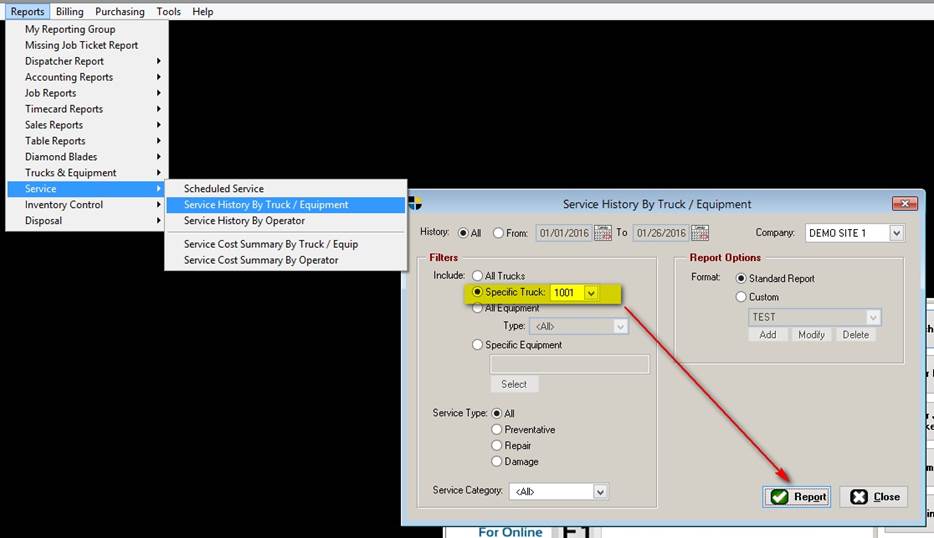

Now,

go to reports > service > Service History by Truck / Equipment. You’ll see the following screen:

Choose

the truck we used for the example. Click

REPORT.

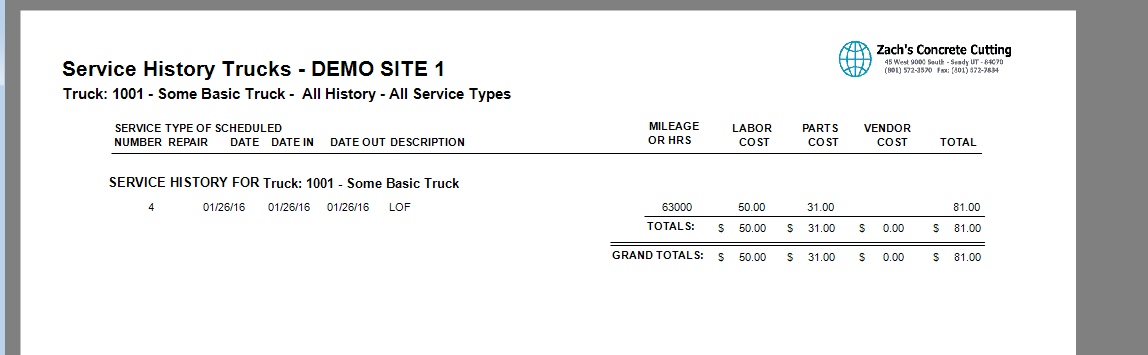

Here,

we can see the basics of what happened.

Since we didn’t track much else, only the basics are shown here.

So,

let’s take this a little further.

Using

the above example, we’ll now add some parts to the scenario such as Filter,

Oil, etc. and show where it all goes.

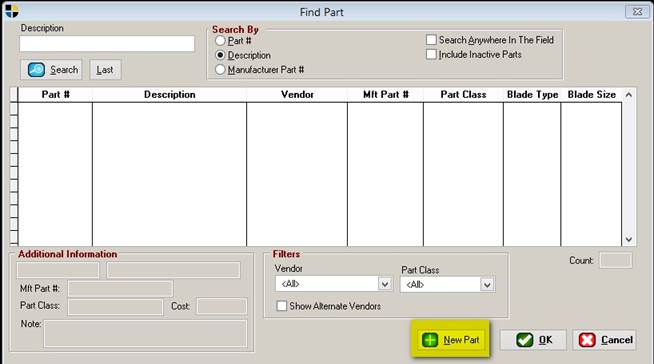

Now,

go to file > Maintain tables > inventory > Parts. (Also can be reached by CTRL+P)

Click

NEW PART.

You’ll

see the following screen:

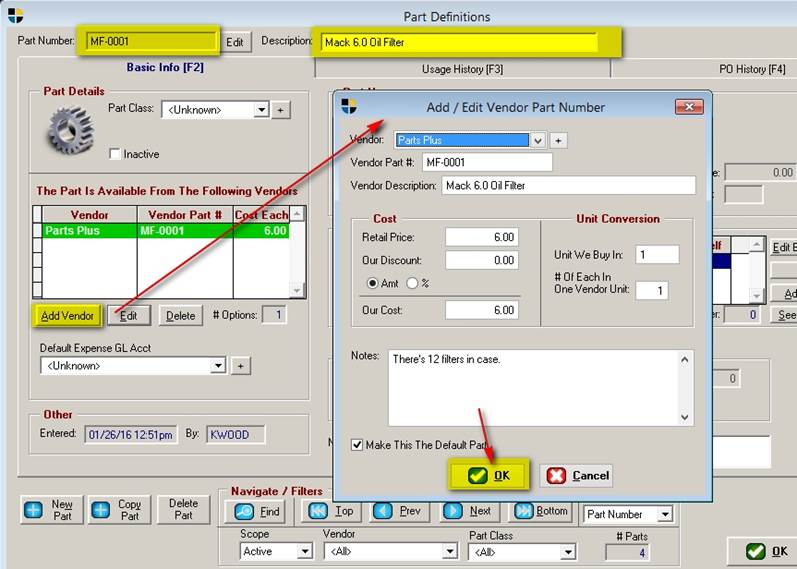

Here’s

where it gets fun. We have to add in a

few parts. Normally they might already

be in your system but we’ll go through this anyway. It’s necessary to do this so that your system

reports properly and you have a handle on things going on. It’s a key to successful business.

Add

the part number and description.

Next,

add the vendor, part number, desc and retail

price. The rest is really up to you but

we’ll do this for this example.

Click

OK when done.

Add

other parts as necessary. For the

example, we added also OIL which will be shown later.

Go

back to the truck. This is also

accomplished quickly by using CTRL + M and select it’s

service records tab.

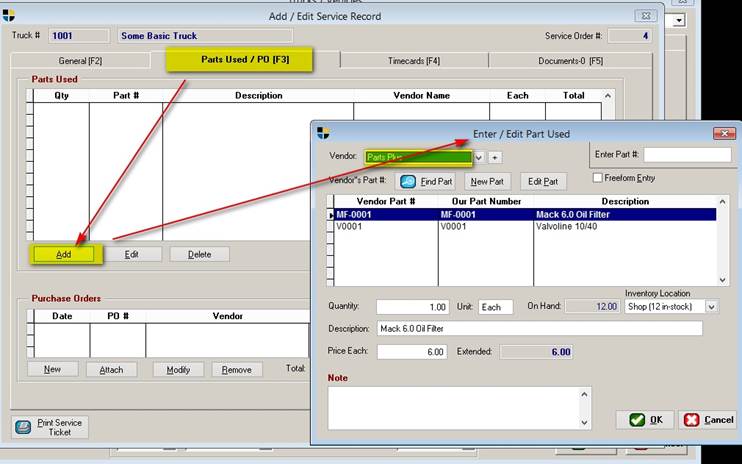

Next, edit that service record and go to the PARTS

used / PO tab.

Click

ADD. From here, we’re going to select

our parts used. Find the vendor and

select the parts you used.

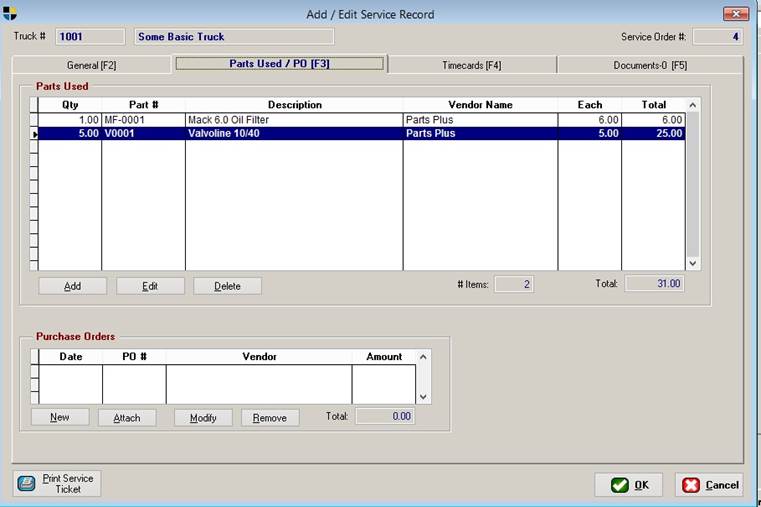

Once

you’ve added the parts you used, click OK and you’ll see the list of items used

on this service record.

With

the parts used filled out, click OK.

Now

go back to the report you’d run before:

You

now are getting a more complete view of things going on:

There

are other reports as well! Let’s take a

peek!

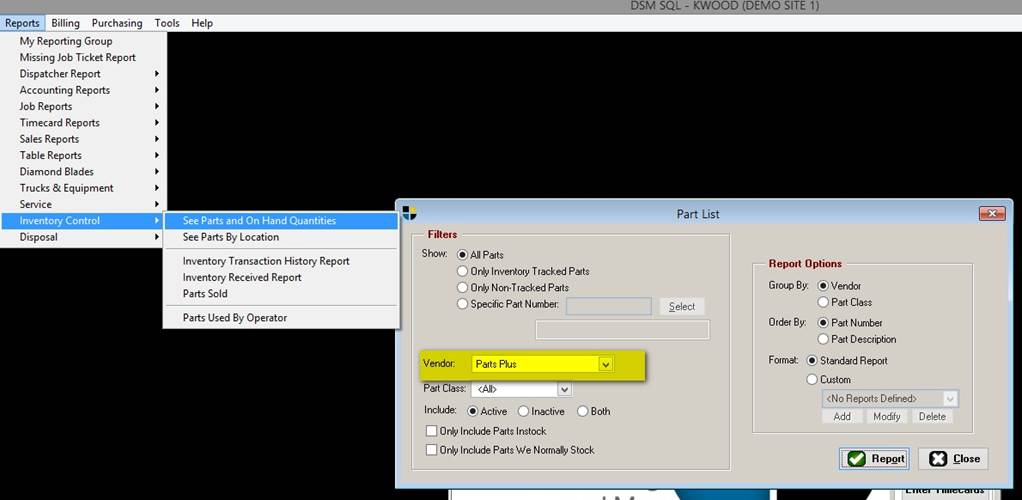

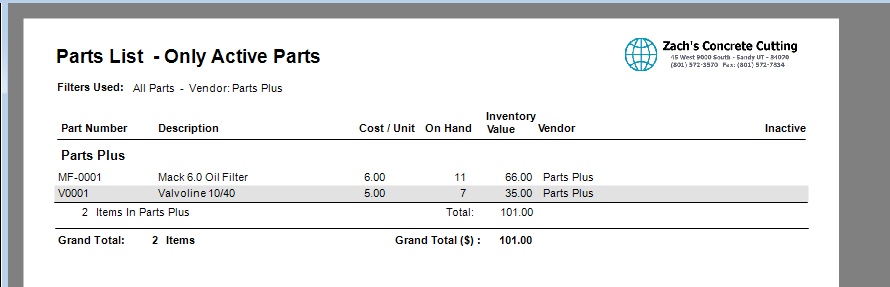

Go

to reports, inventory Control, see parts and on hand quantities. Select your vendor you just used.

And

now you know what you have left.

But

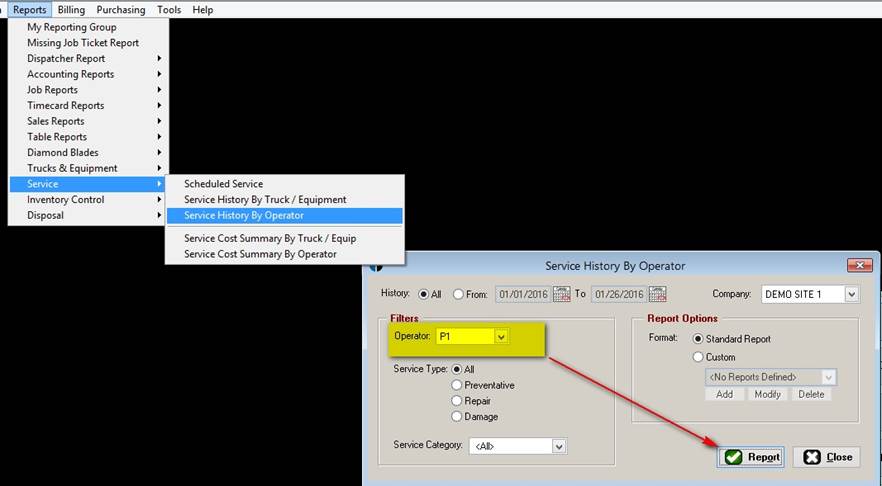

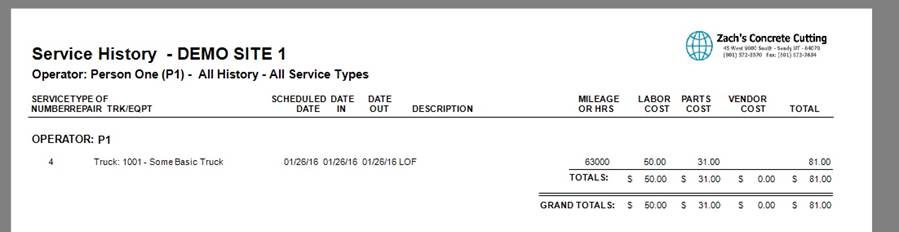

Wait! There’s more. Let’s take a look at some service history by

Operator! This gives you an idea of

who’s treating their equipment right by seeing how much it’s in the shop!

And

the report:

End of document.